Industrial sector with the need to be increasingly competitive in a variable environment

Opportunity to accompany our historical customers in this transition through an integral, modular solution, easy to implement and embedded with the best market practices

Need for a transition from workshop to industry

Opportunity to be the technological partner of our clients

In this phase, a comprehensive analysis of the company's specific processes and requirements is conducted.

In this phase, specialized training is provided to the teams responsible for using F-Evolution.

In this stage, the implementation of F-Evolution software takes place in the company..

During the testing phase, comprehensive tests are conducted to verify the performance and functionality of the F-Evolution system.

Once the tests have been successful, the official launch of F-Evolution in the company takes place.

This phase involves continuous support and assistance after the launch.

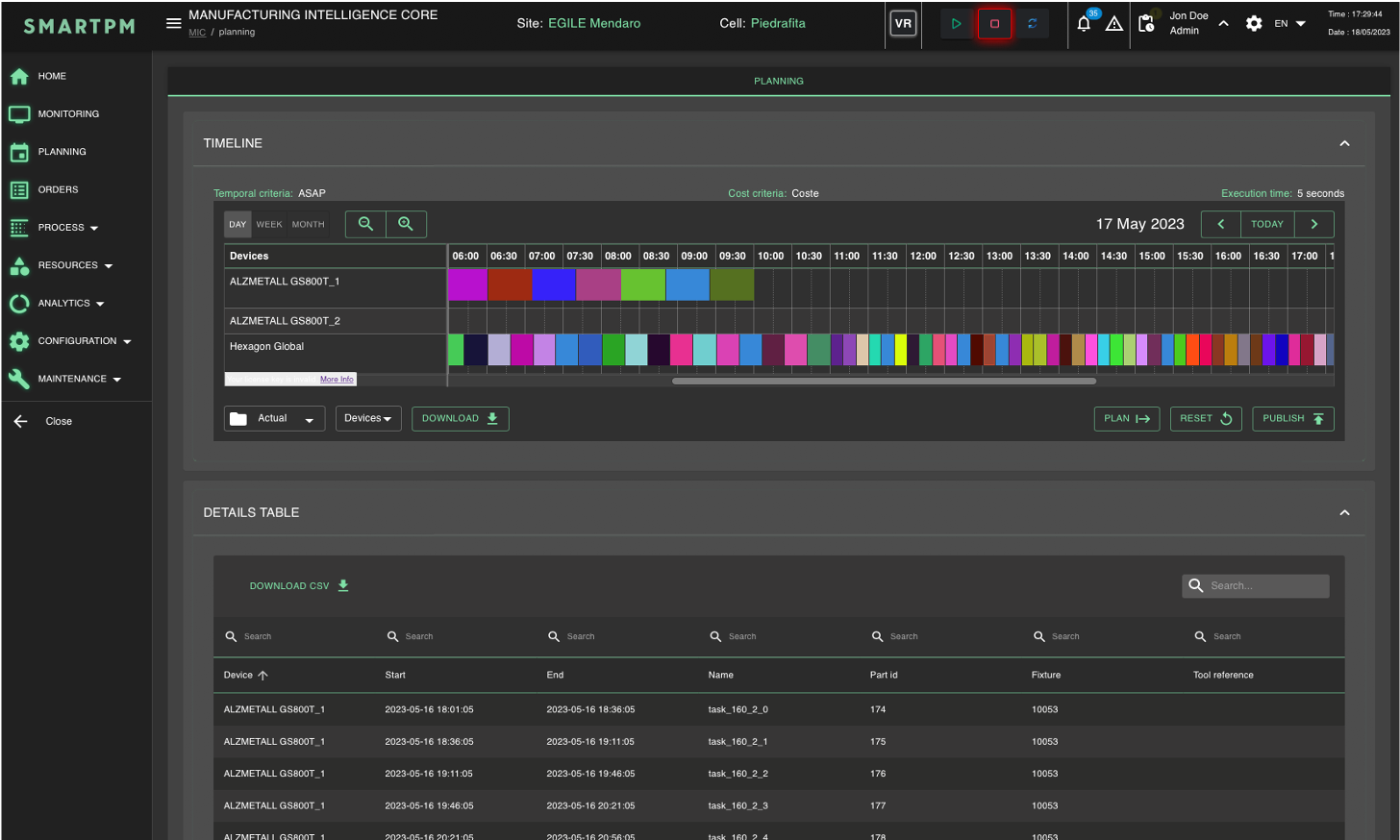

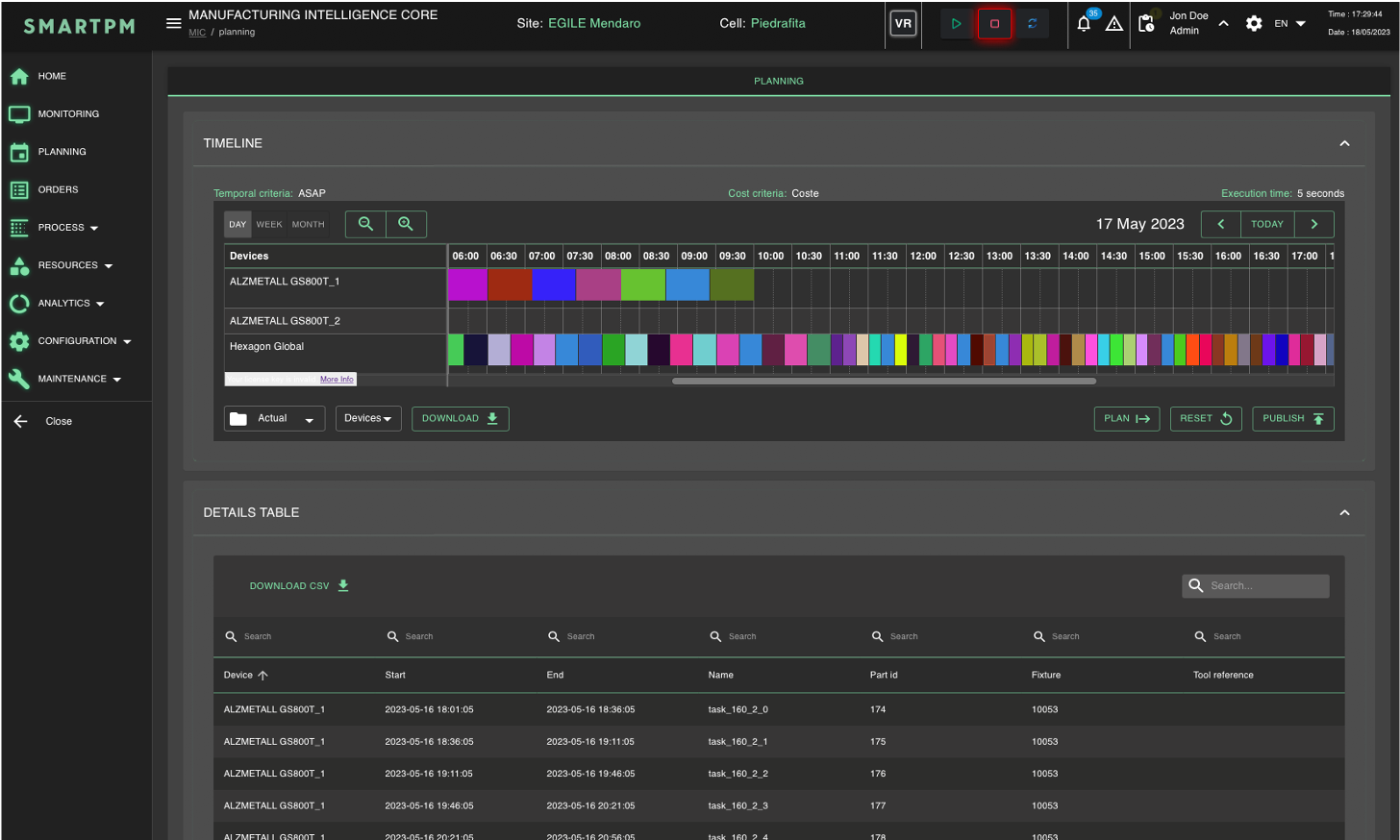

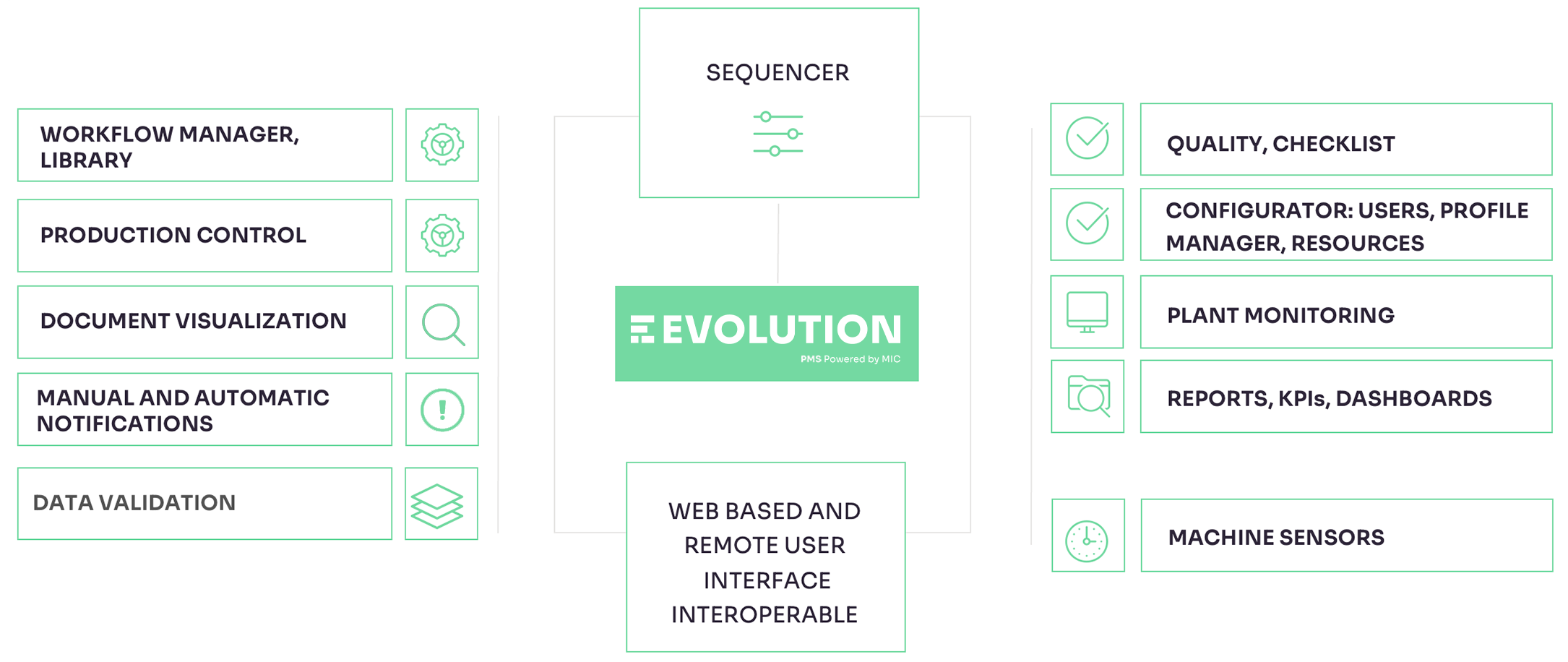

Basic planner for assigning activities to resources (equipment and workers) over time according to the input from O.Manufacturing

Generates production sequences (queues) in the assets

Possibility of manipulating the sequences manually by operators replanning functionality

All pieces go into sequencing Possibility of estimating the use of resources (allows detection of saturation and bottlenecks by the operator)

DOES NOT include optimization criteria

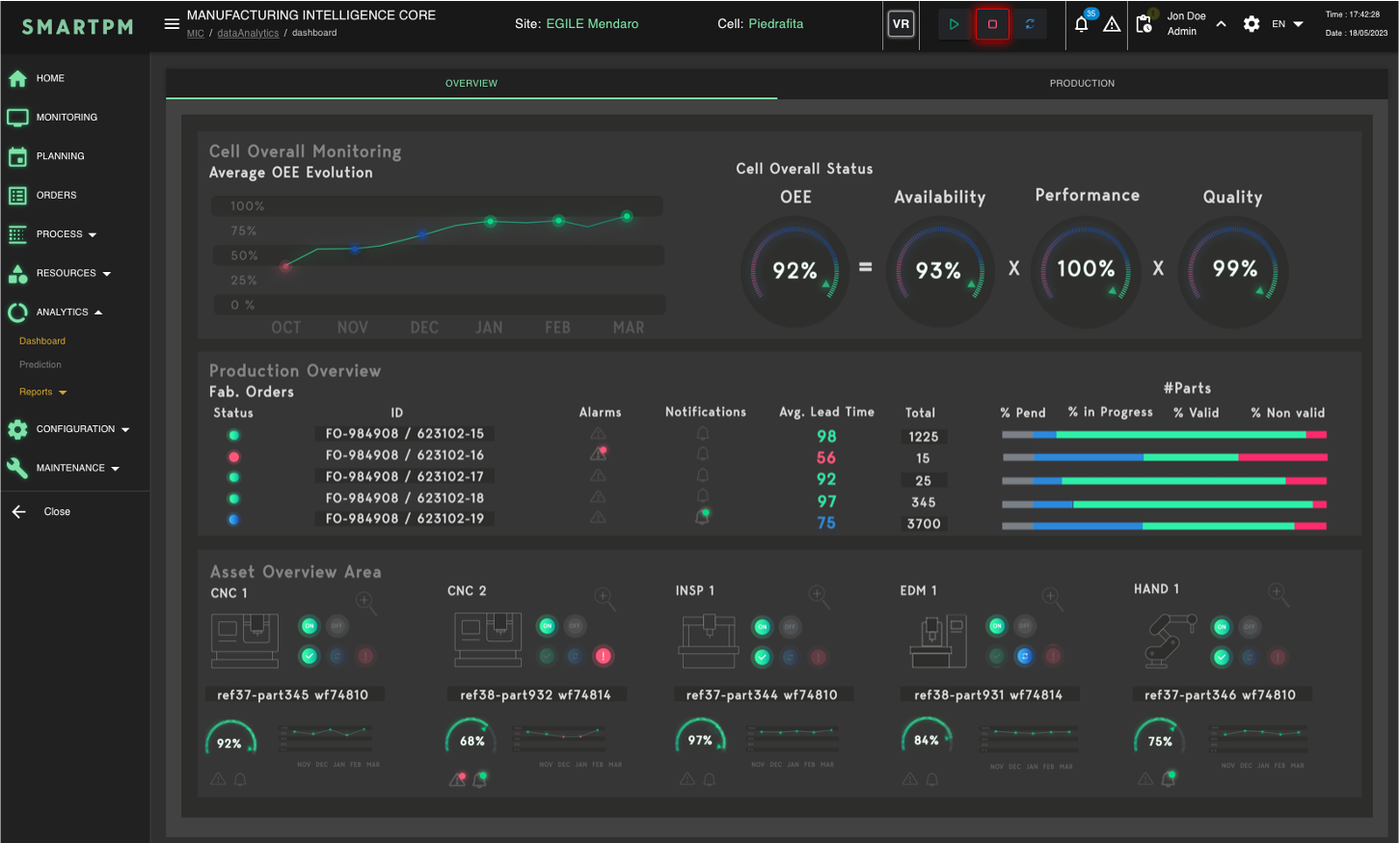

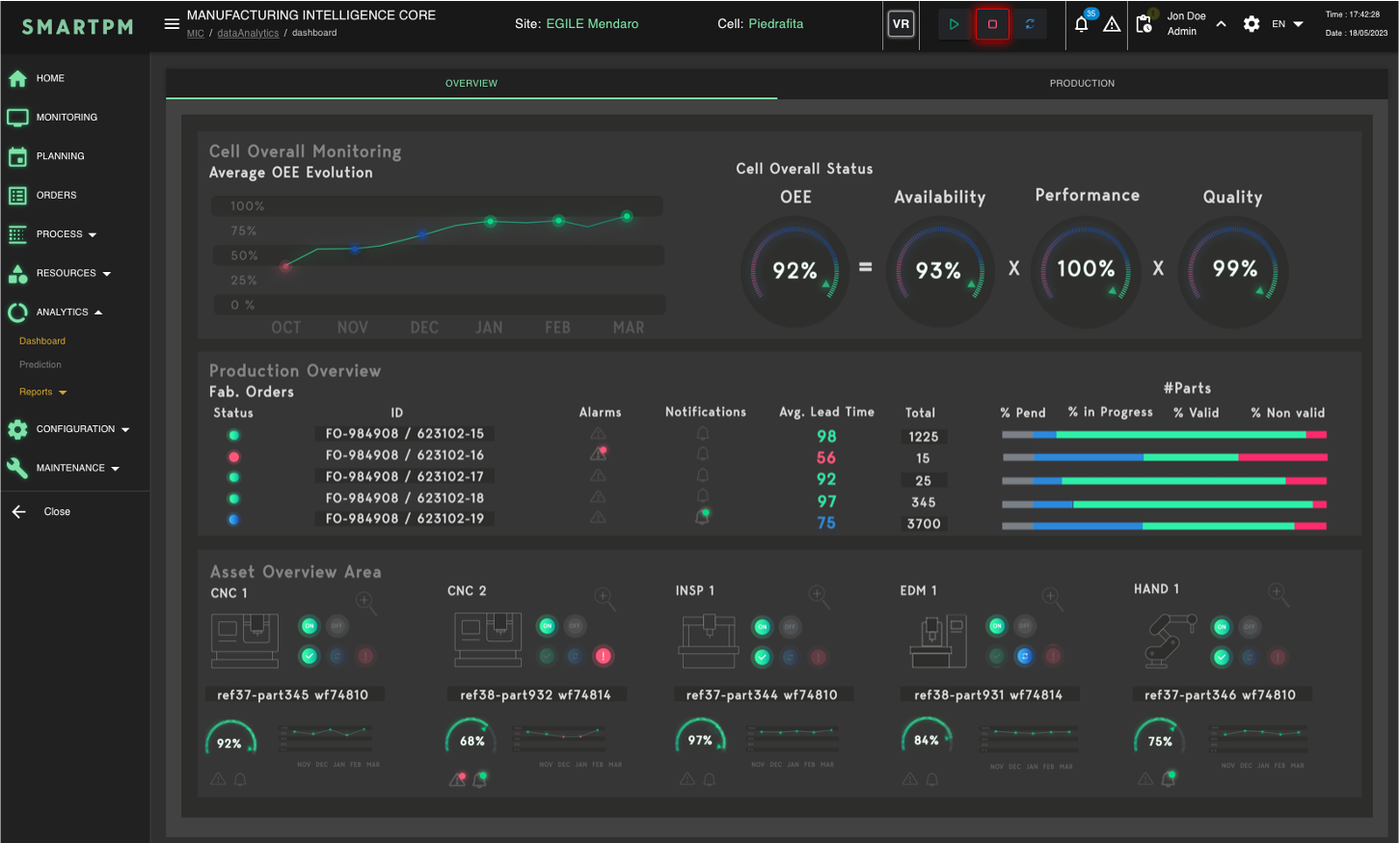

Plant monitoring (assets and their status)

Generation and visualization of KPIs, OEE

Availability, Performance, Quality

Possibility to filter / add the information by assets / OF / reference

Generation of real consumption/times and comparison vs. Forecast

Generation of expense allocations to analytical units

Generation of files for sending to external systems

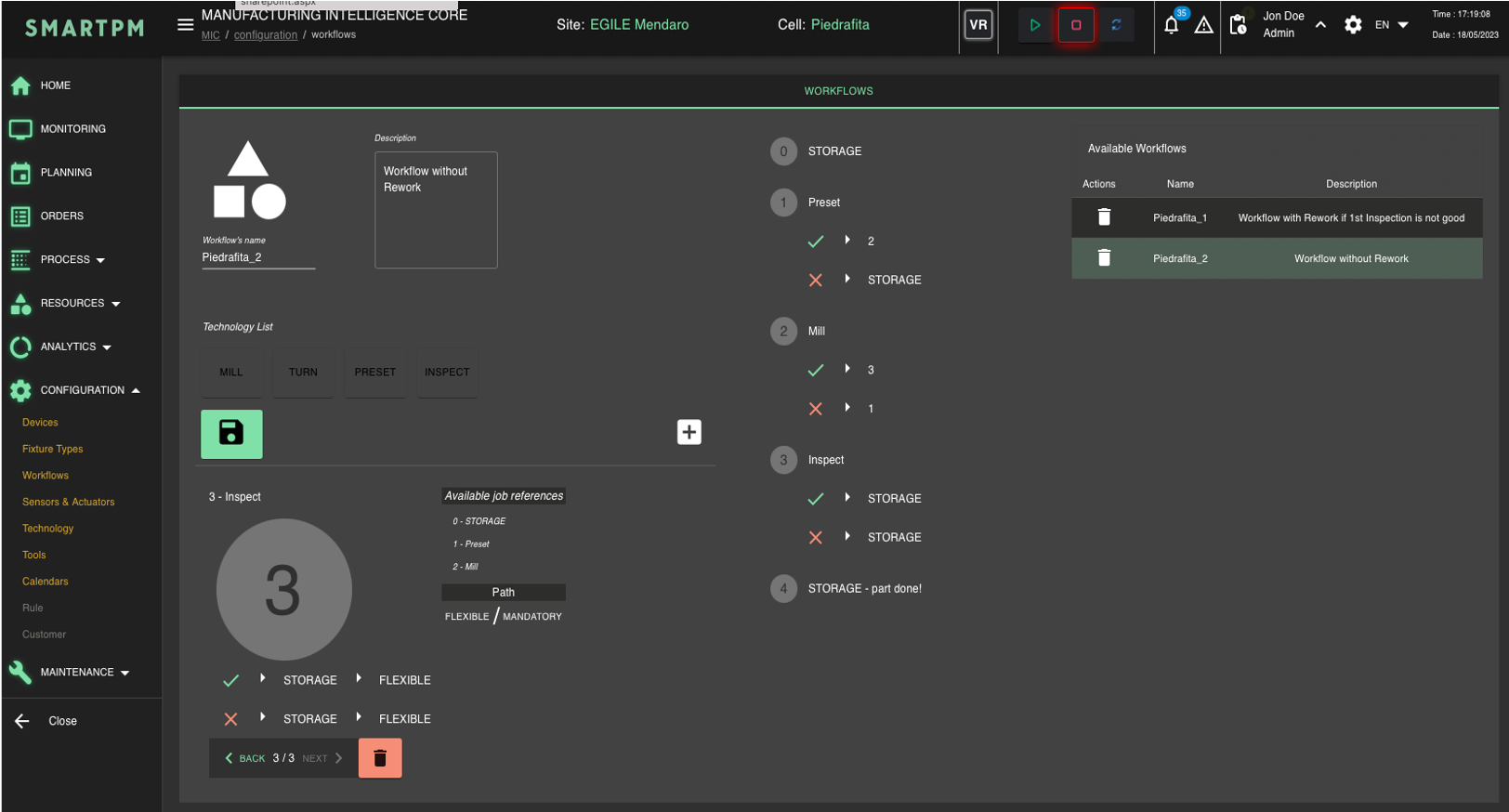

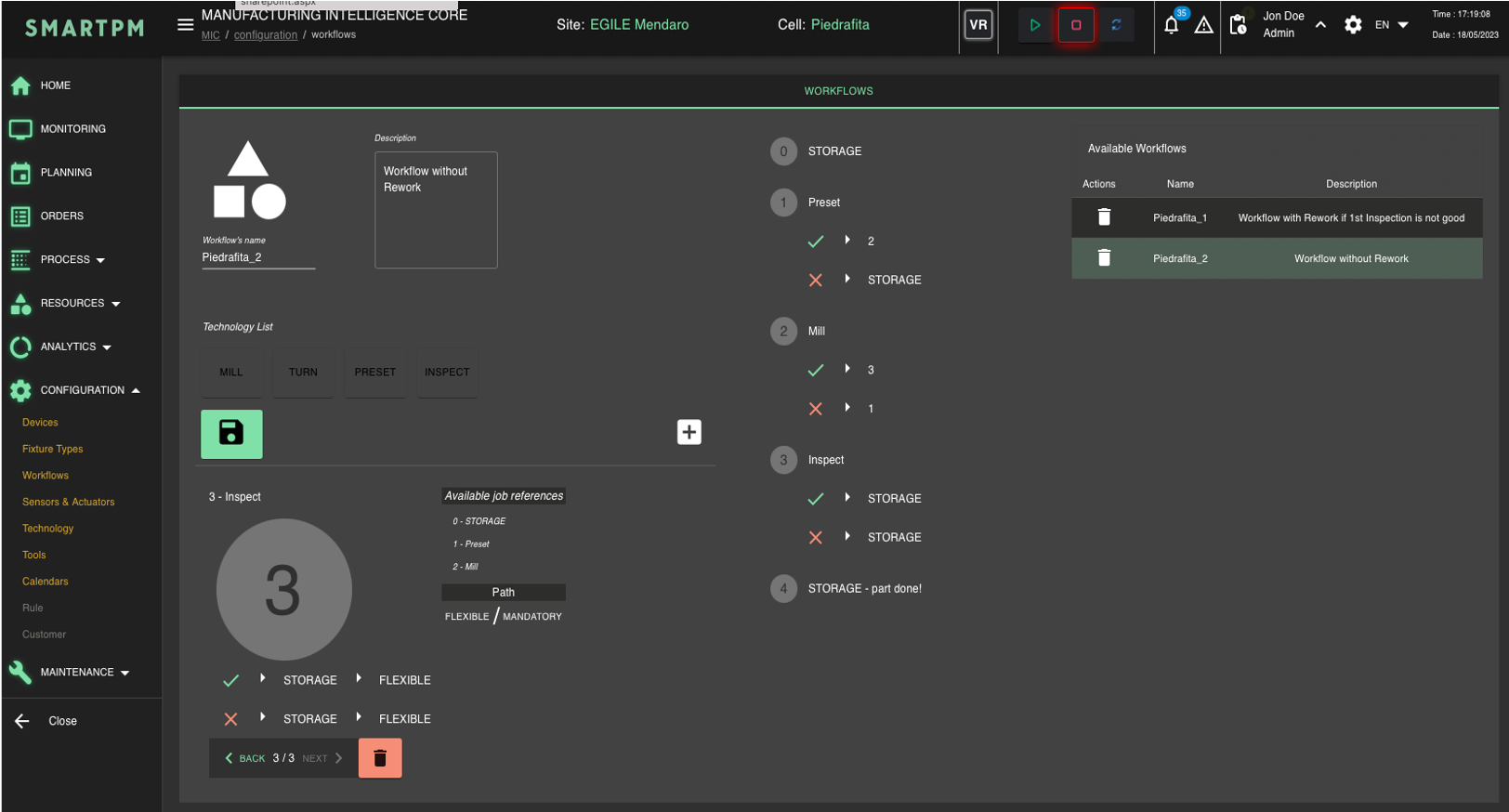

Workflow (Product Structure -> production and inspection guidelines)

workflow library

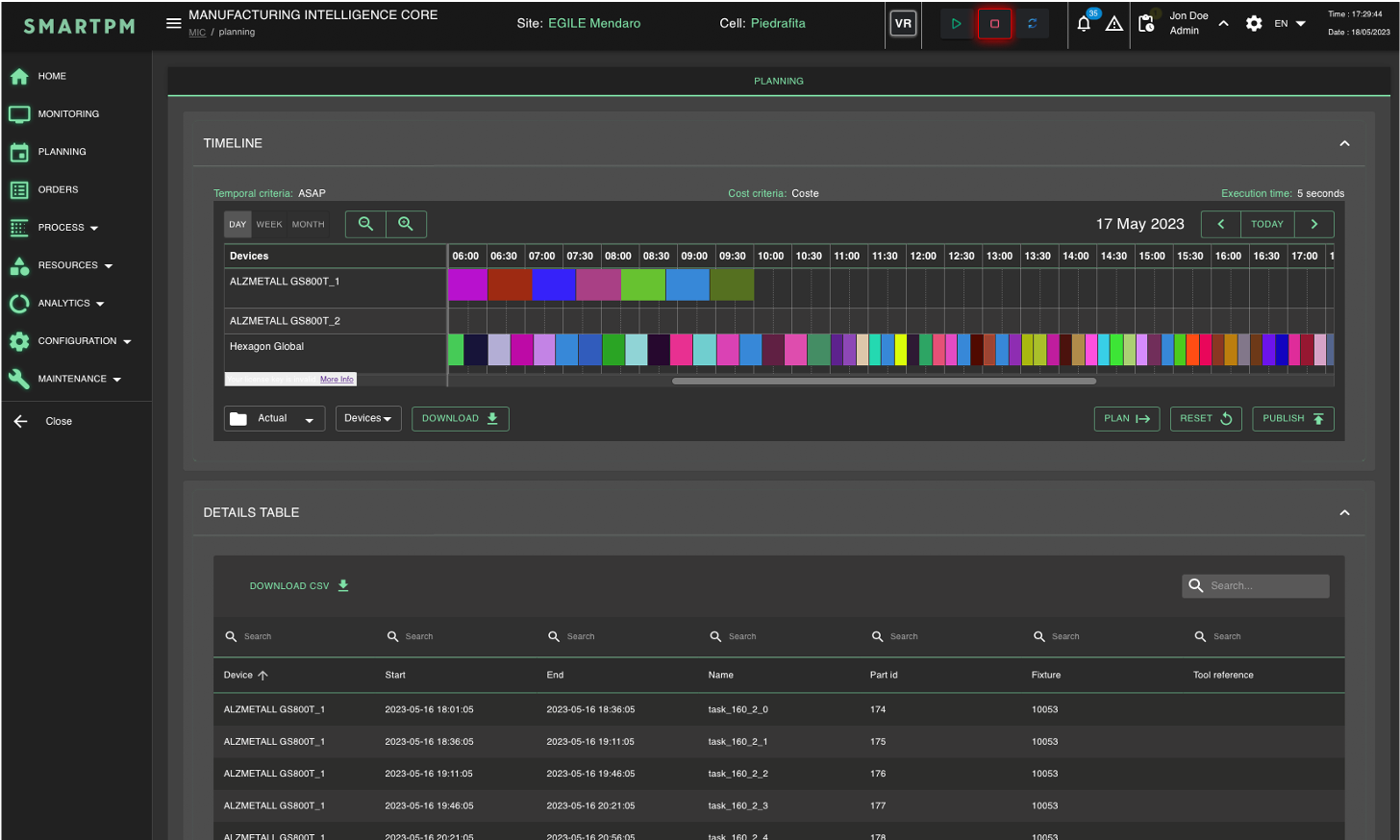

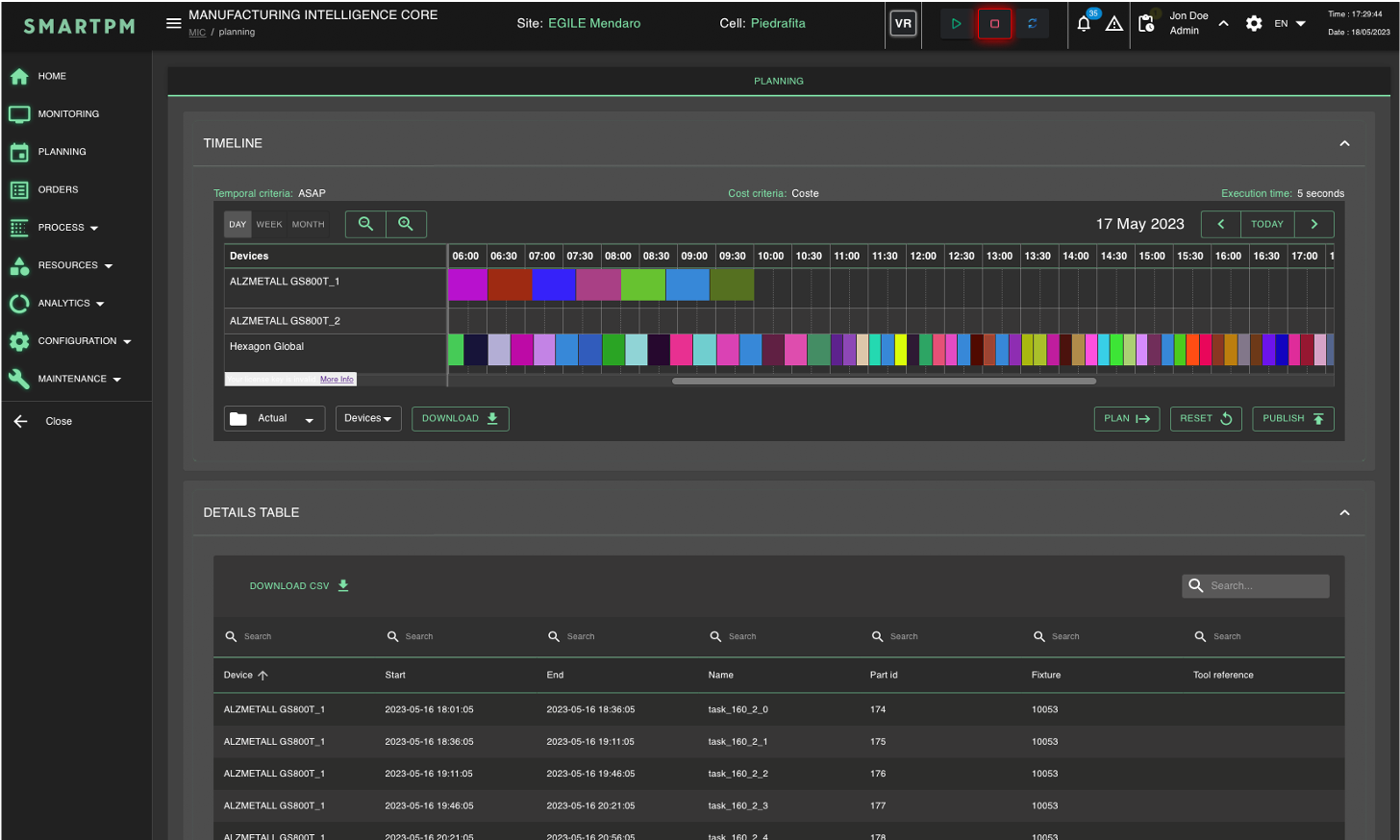

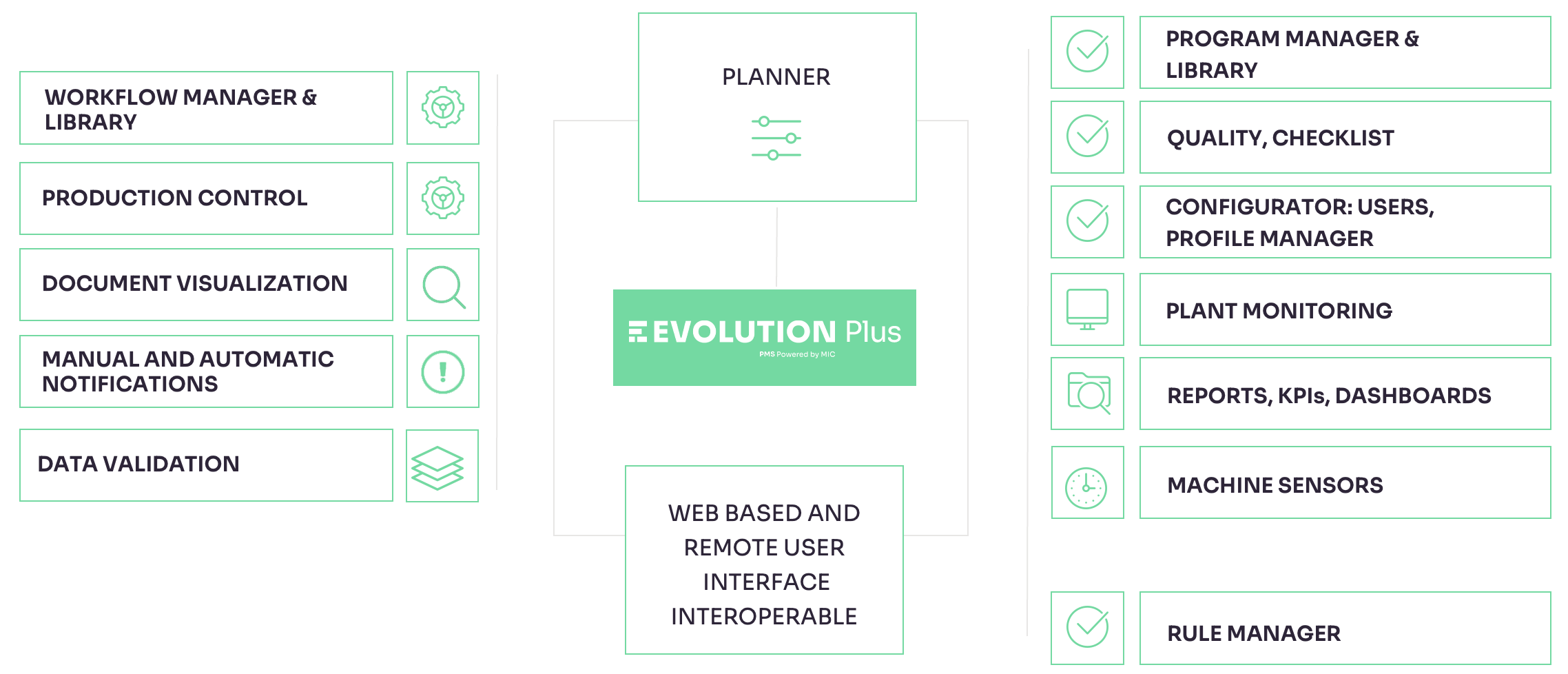

Complet planner for assigning activities to resources (equipment and workers) over time according to the input from O.Manufacturing

Generates production sequences (queues) in the assets

Possibility of manipulating the sequences manually by operators replanning functionality

All pieces go into sequencing Possibility of estimating the use of resources (allows detection of saturation and bottlenecks by the operator)

INCLUDES optimization criteria

F-Evolution can enable precise real-time tracking of critical components, ensure compliance with specific regulations and standards, and enhance aerospace production management.

F-Evolution can enhance efficiency in the assembly line, manage traceability of parts and components, and optimize quality control in automobile production.

F-Evolution can optimize metallurgical process management, control and supervise real-time production, and enhance efficiency and quality in metal and steel manufacturing.

F-Evolution can help manage complex manufacturing processes, ensure compliance with quality and safety standards, and facilitate lot tracking and traceability.

mmmm

F-Evolution can manage quality control in textile and garment production, improve material efficiency, and help meet delivery deadlines in the textile industry.

F-Evolution can help manage complex manufacturing processes, ensure compliance with quality and safety standards, and facilitate lot tracking and traceability.

F-Evolution can provide end-to-end supply chain visibility, enhance inventory and materials management, and optimize efficiency in electronic product manufacturing.

F-Evolution can optimize metallurgical process management, control and supervise real-time production, and enhance efficiency and quality in metal and steel manufacturing.

Fill out the form and our team will get back to you as quickly as we can.